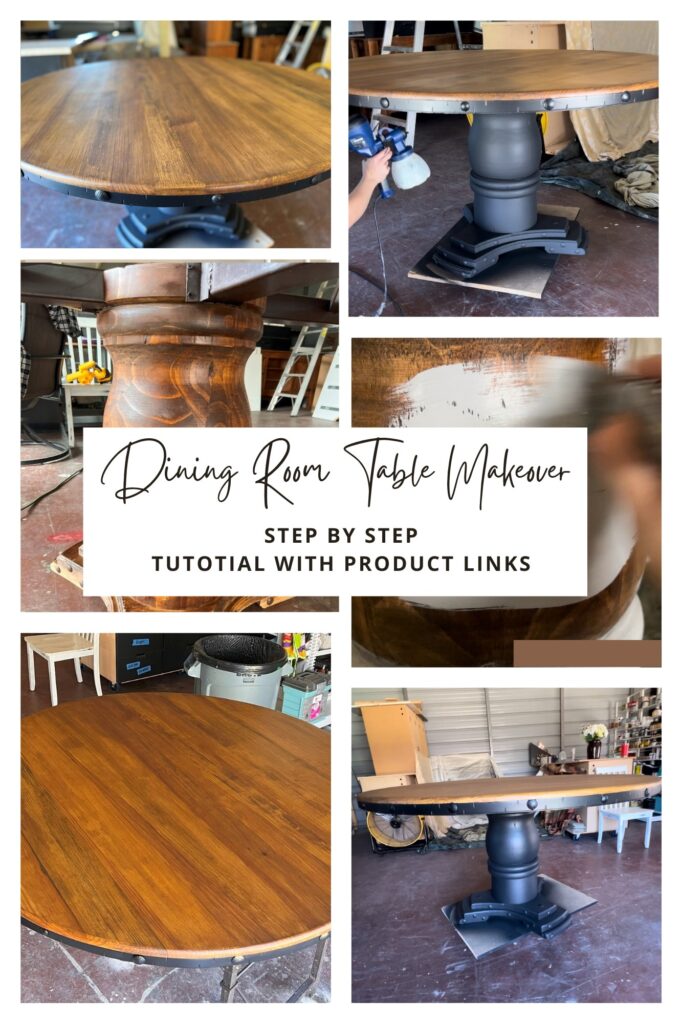

BLACK & STAINED

DINING ROOM TABLE

FULL TUTORIAL

DINING ROOM TABLE

FULL TUTORIAL

Ready to start selling furniture for a profit?

I have been flipping furniture (for profit) since 2019 & am finally ready to share some of the knowledge I have gained from my own successes & failures.

In this blog post, I will share step by step how to replicate this furniture flip with product links! You will also find a huge learning opportunity with a problem that came up during this flip- Find out what that problem was & how I fixed it!

HAPPY FLIPPING!

BLACK & STAINED DINING ROOM TABLE MAKEOVER: FULL TUTORIAL

Furniture Backstory:

A friend of mine scored this table off Facebook Marketplace for $100.00! She asked me if I could help her bring it back to life and of course I was up for the challenge!

Client Request & Inspiration:

– Black painted base

– light semi-transparent stain (she really wanted to be able to see the wood grain)

– Replacement of Metal decorative nails that were missing

Just from the pictures provided of the table- all of her requests appeared to be doable. I did however, mention that in the chance the wood was in bad shape- we would have to come up with an alternative application method to achieve the look she wanted while assuring her that in the end, I would make sure that table ended up being beautiful.

Supply List

Prep & Clean

- Orbital Sander

- Sanding pads

- Microfiber rags

- Lint Free Rags

- pre-taped plastic

- Cleaner: white lightening

- Painters tape

- Oven Cleaner

- scrub brush

- Lacquer Thinner

Table Top:

- Paint sprayer

- Stain: Early American

- Stain2: Golden Pecan

- Wood Conditioner

- Clear Coat: Semi-Gloss

- Washable Sanding sponge

- Spray Paint: Black Matte Finish

- Custom Tint Wood Filler

- 0000 Steel Wool

- Dixie Belle: No Pain Gel Stain

- Clear Glaze

- Coarse Bristled Brush

- Chip Brush

- Replacement Decorative Nails

- Glue for Decorative Nail replacement

Table Base

- BOSS Primer: Grey

- Dixie Belle Oval Medium Paint Brush

- Paint color: Midnight Sky

- Clear Coat: Semi-Gloss

- Washable Sanding sponge

- Paint sprayer

Step 1: Clean

I started with a thorough clean using Dixie Belle Paint Company White Lightening Cleaner and a microfiber rag.

Then, I taped off the metal edge before using the oven cleaner stripping method to help remove as much of the original stain as possible before taking my sander to it.

Step 2: Oven Cleaner Stripping Method

I sprayed a heavy coat of oven cleaner to the surface, let it do its work for about 20 minutes and then started scrubbing with a scrubbing brush. (I got the scrubbing brush I’m using from the Dollar Tree but a did provide a link to one available on Amazon)

I gave it a really good scrubbing and used a wet microfiber rag to remove the build up. Once I had wiped off all of the build up from the oven cleaner- I set up my shop fan to help with the drying process.

Step 3: Sanding

2 hours of sanding later & I was finally able to get a good look at the condition of the wood I was working with & what I found was going to create some challenges.

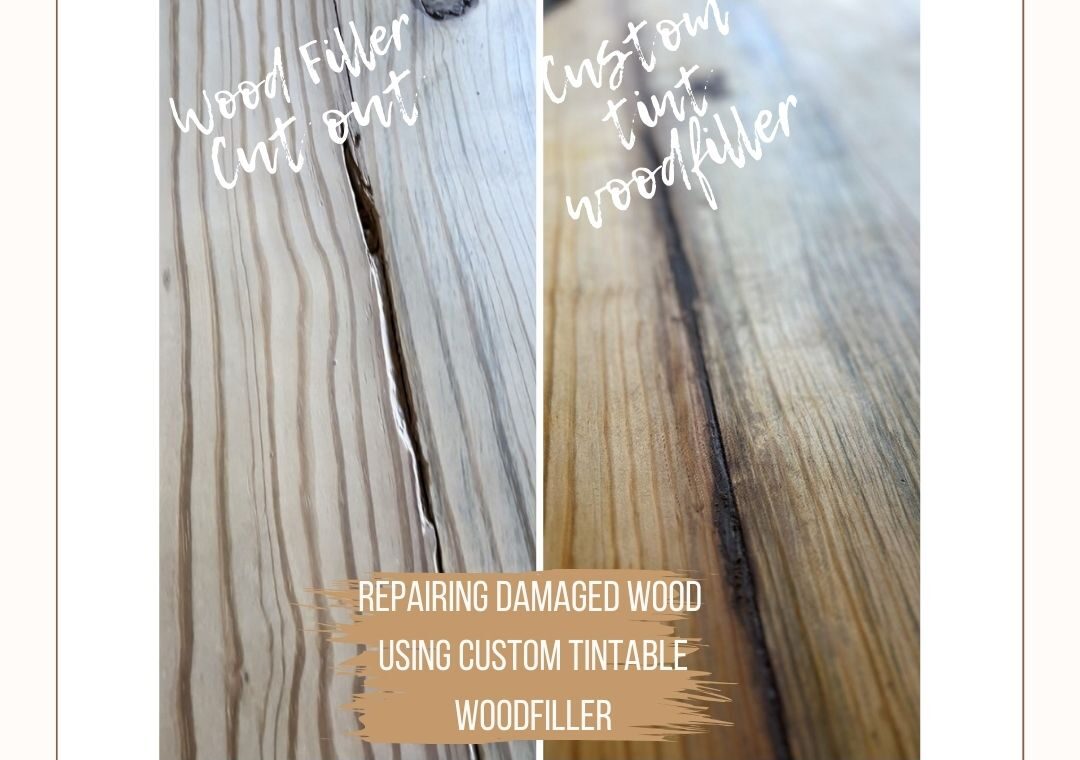

PROBLEM 1: It appeared that a non-stainable wood filler was used to make some repairs at some point…In order to accomplish the light stain request- I was going to have to get creative…

I grabbed a couple pieces of scrap wood & added some Bondo wood filler (non-stainable)- then I tested a handful of techniques & stain combinations to see what my best option for covering these areas was going to be… unfortunately, nothing I tried was going to cover these areas…

Step 4: Wood Filler Removal & Repair

After exploring multiple options with no luck, I ended up deciding to cut out the wood-filled areas so that I could repair with a stainable product. I used an exacto knife to carefully cut & chip away at all the areas where this non-stainable wood filler was present..

I then finished my sanding of the wood top by going from 40grit moving all the way gradually changing grits to a 220grit… This process took approx. 7 total hours to complete… I was removing several layers of stain that were previously applied to this wood…

To repair the areas that I cut out- I used a custom tintable wood filler by DAP using a separate container to mix the compound with the stain mixture I planned to use.. because I there was no way of knowing what the exact color would look like once I applied it to the table until I actually applied it… I decided to make the filler color a little darker than I planned to stain the table- A color that would match closer to the natural darker grain in the wood… My hope was that I could mask the large gap as a natural part of the wood grain rather than trying to make it a part of the end stain color…

STEP 5: WOOD CONDITIONING

Next, I applied my wood conditioner. I applied my wood conditioner with a clean old sock. If you don’t have a pair of old socks- use a staining pad or lint free rag.

step 6: Metal Spray Paint

Once this was dry, I decided to get the metal rim around the tables edge painted before I stained- My thought here was that, if for some reason I had any over shoot under the tape onto the unfinished wood- It would be easier for me to fix this before I stained…

For this step, I took my pre-taped plastic and wrapped the top up tight. I then scuffed the metal with a general purpose sanding pad & cleaned with some laquer thinner and a rag. I then took my Matte finish spray paint and applied multiple coats until I achieved full coverage. Once this was dry, I removed the plastic and was ready to start staining.

STEP 7: STAINING THE WOOD TOP

I used a custom mixture of Minwax stains in the shades Early American and Golden Pecan to create a light stain that would have a dark enough tint to mask the uneven transitions of the wood that were joined together.

Once this stain was dry, I applied a second coat of the Minwax stain mixture….

I will be writing a post about applying wood stain in the future- so check back for that!

PROBLEM 2: Unfortunately, due to the high concentration of sap that emerged during sanding, I needed to come up with a creative way to even out the color.

STEP 8: using glaze to even out the color

Using what I had on hand, I mixed a 1:1 ratio of no pain gel stain in the color (golden ash) with some clear glaze– I then brushed this glaze mixture on using coarse bristled brushes in the same way you would to accomplish the “faux stained” technique.

This stain ended up doing exactly what I wanted to do & evened out the color perfectly…

This is what it looked like before and after the glaze.

<< I used the faux stain technique on my bathroom cabinets- check that video out here.>>

If you would like me to do a full tutorial on this technique, let me know in the comments!

Step 9: the table base

With my glaze now drying, it was time to transition to base of the table.

Let’s “paint it black” baby!

Table Base Paint Steps:

Light Scuffing with a sanding sponge

Remove dust (I like to use a combination of cleaning techniques to ensure all of the dust is removed by using my mini shop blower & dusting with a clean pillow case or dry microfiber rag)

Primer Application: Using my Dixie Belle oval medium paint brush, I then applied 2 coats of BOSS grey primer. I allowed each coat to dry completely, giving the base a light scuffing with my washable sanding sponge between each application.

Paint Application 1: I then used my paint sprayer to apply my first coat of Dixie Belle Paint Company chalk mineral paint in the shade: Midnight Sky.

Scuffing & Dusting: Once the paint was dry, I took my sanding sponge & gave it a quick scuffing & dusting.

Paint Application 2: I then brushed my second coat of paint on with my oval medium brush & allowed to dry.

Top Coat Application: Using my paint sprayer The entire piece was then sealed with 4 coats of General finishes semi-gloss top coat. I let each application dry completely & lightly sanded with 0000 grit steel wool between each clear coat application. This is going to allow you to achieve a uniform & smooth clear coat finish.

Question: Why did you apply 4 coats of your top coat for this project?

Answer: GREAT QUESTION! The reason I chose to apply 4 coats of my clear coat on this project is because of how much use it would get. Knowing the intended use for each piece I flip determined how many coats of my clear coat I use.

PRO TIP: How to determine # of top coat applications

These are generally the rules I follow when determining the number of top coat applications to use.

Décor (light use): 1-2 coats

China cabinets & dressers (medium use): 2-3 coats

Bathroom/Kitchen Cabinets or Tables: 3-4 coats

Outdoor furniture: 4+ coats

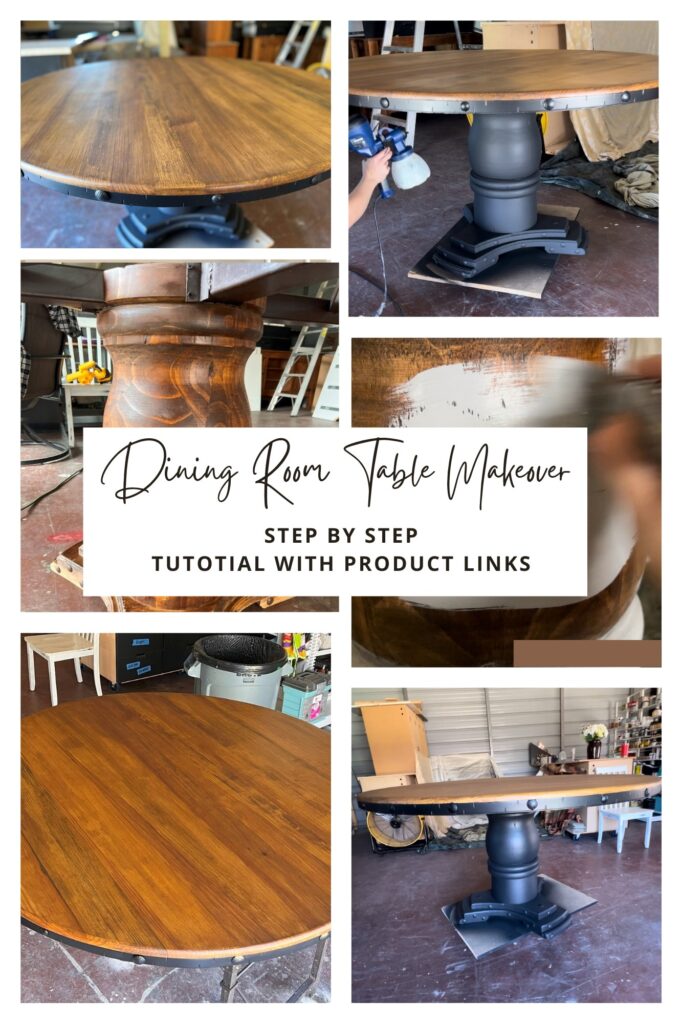

& Finally, the big reveal!

Lets take a look at the before and after!

How do you think it turned out? I love it!

In the end, I think this flip turned out beautifully and my client was thrilled with the result!

I have 7 years of experience working painting & refurbing furniture. Yet, I still learn something new from each project I take on…

If you are new to the furniture flipping game, I encourage you to be patient, experiment with new techniques and styles, and use the information & recommendations available to you from blogs & social media to guide you on your journey.

Like any trade, flipping furniture is A LOT of work but YOU CAN DO HARD THINGS, Queen!

Don’t give up and stay true to your brand. Learn from your mistakes and never stop investing in yourself. You won’t become a high roller in this business overnight. Take your time, invest in the right tools and believe in yourself! Find a tribe of like minded women for support on your creative journey for quick advice and find a mentor that inspires you to keep going and when you make it, pay it forward.

If you enjoyed this flip, drop a comment and be sure to PIN it for reference!

Thank you so much for your support!

I hope that you found this tutorial helpful & would love your feedback! If there is a particular topic, product, technique, etc. that you would find helpful, please leave a comment or send me an email!

As always, I am here to help! Welcome to the tribe!

- Reconciliation Furniture

dont miss out on any of the fun!- follow me:

PIN THIS POST!

FOR REFERENCE LATER..